When the new 1967 390 GT Mustangs were released in the fall of 1966, Ford executives believed that they would be able to match the performance of cars from Chrysler and GM. It soon became evident that they had misjudged the market and what it would take to be competitive. Bob Tasca, the owner and president of Tasca Ford, a performance-oriented dealership with the second highest volume in the nation, decided that he had to do something to remedy the situation. His first step was to have Billy Loomis, one of the street performance mechanics, develop some simple parts and tuning tricks to hop up the 390 GT. The kits helped, but they recognized that more had to be done if Ford was ever going to be able to establish a credible presence on both the street and strip.

Tasca’s next step was to leverage the strong relationships he had built with Henry Ford II and other executives at Ford to sell the case for building a true street performance vehicle. Tasca met with Ford and pointed out that the successes at Le Mans, Indianapolis, and elsewhere in professional racing had not resulted in measurable sales of performance vehicles. In fact, it had diverted attention away from producing street cars that could match those from Chrysler and GM. Compounding the poor sales was lost opportunities in the area of merchandising and public relations relative to the youth market.

Throughout the fall of 1966, Tasca kept the pressure on, using his influence to spur a series of discussions within Ford management which included the impact of ethics, liability, safety, insurance, and cost relative to building and marketing regular production high performance vehicles. The discussions included plans to address some of the organizational deficiencies that had been identified as part of the review process. The result was a formal shift in Ford’s focus towards producing vehicles that met the strong demand for stock performance cars including more aggressive marketing of street performance cars.

In December 1966, the decision was made to initiate development of the “Cougar – Mustang Performance Car”, which would eventually evolve into the 428 Cobra Jet program. Key areas for development included a reliable and affordable performance engine, an effective locking differential, and a suspension and tire combination that would be capable of applying the increased power to the pavement.

The most obvious option available to Ford was to install their race proven 427 cubic inch engine into the Mustang/Cougar and the Fairlane/Cyclone models for 1968. The problem was that the operation of the solid lifter 427 was considered too harsh to meet regular production vehicle acceptance standards. A design effort was quickly initiated to produce a hydraulic lifter version for smoother and more reliable operation. This was only a short-term fix as it was clear that the 427 was not practical to produce in high volume. Manufacturing would be limited to a maximum of a few thousand engines per year based on the availability of machines and tooling required to locate and bore the block at the Dearborn Engine Plant (DEP). Ford’s component supplier base for the 427 also had limited capacity. The Engine Engineering department ultimately decided that it would be better to use the existing 428 passenger car block as it was adequate for the planned performance level and could be produced in much larger numbers using existing resources.

In January 1967, Bill Barr was selected to lead the Engine Engineering department’s effort to develop the 428 for performance applications. According to Bill, his team, including Paul Lampella, Bob “Jumpy” Snyder, and Frank Gondoly, immediately kicked off a design analysis effort focused on optimizing the cylinder heads and intake manifold for the new engine. They established how much space was available under the hood line of the Mustang and Fairlane and used that dimension to establish the maximum possible height of the carburetor mounting flange. The ports were designed to have a downward pitch all the way to the intake valves. The intake featured a four-hole carburetor mounting pad with a back-cut radius on the bores that was found to improve air flow and throttle response. The cylinder head design was initially based on the C3 and C4AE-6090-H 427 low-riser heads, however the final design incorporated a significant number of changes as evidenced by the 5-sheet detailed design drawing for the 428 CJ head. New valves were designed incorporating a smoother stem to head transition and swirl polishing to improve air flow and heat transfer up the stem. The water jacket was also modified to improve cooling and address valve seat issues that were being experienced with FE passenger car heads. The exhaust ports and manifolds were optimized based on the limited space available in the Mustang engine compartment.

Design and development work for the intake, heads, and exhaust manifolds continued through mid-September 1967 when the initial design drawings for the heads and intake were approved. Subsequent drawing revisions continued through the end of April 1968. The exhaust manifolds, particularly the passenger side, took much longer to get through approval due to strong objections from the Body & Assembly (B&A) group. The B&A group claimed that it would be too difficult to install the engine with the extended passenger side manifold in place. After a few months of discussion, Barr’s team had 3 development engines built which were successfully installed in Mustangs at the Dearborn Assembly Plant (DAP). This finally convinced the B&A group that engine installation with the 428 CJ exhaust manifolds could be completed as easily as with a 390 GT.

There are two other cylinder heads whose designs were based on intermediate configurations of the 428 CJ heads. The design for each of these heads was taken from the parent drawings for the 428 CJ. Each reflects the state of development for the 428 CJ heads the time they were created. The first configuration was the C8OZ-6049-F (C8AE-6090-J engineering number) 427 head which was approved on March 23, 1967, and continued to evolve through several revisions until early November 1967. The second was the C8WE-6049-A (C8WE-6090-A engineering number) cylinder head, which was initially approved on April 19th, 1967, and was revised multiple times through mid-November 1967. 427 Cougar experts confirm that some of the early 427 Cougars were built with these cylinder heads while later production vehicles transitioned to the “J” cylinder heads. A similar head with engineering number C8WEM-6049-A (the “M” stood for Manufacturing) was called out for engines installed in the 50 “135” cars built in December 1967. For some reason, the “135” cars were actually built with the 427 “J” heads. By the middle of January 1968, the initial 14 bolt exhaust 428 CJ -N heads were cast and assembled followed by the 16 bolt production heads cast beginning in March 1968.

A new carburetor was developed based on the 780 CFM Holley with the inclusion of “dog leg” primary boosters from the truck carburetors that significantly improved atomization and also included modifications to the idle transfer slot to improve transition response. A ¼-inch thick phenolic spacer was installed between the carburetor and the intake manifold to help to reduce heat transfer between the intake and the carburetor.

The 428 CJ short block was based on the nodular iron crankshaft and passenger car block which had just been revised to add additional webbing in the main bearing bulkheads. A number of modifications were made to the rotating and reciprocating assembly, including adding larger bolts and nuts to the 390 GT rods for improved durability, new flat top pistons, a nodular cast iron flywheel and larger cast iron bellhousing, a new balancer, and bearings. The existing hydraulic tappet 390 GT cam was selected instead of the planned C8AX-C cam in order to optimize performance and drivability.

Preliminary design work for the new equipment had progressed enough that by May, the effort to fabricate tooling and parts necessary to complete development, tuning, calibration, and emissions certification had begun. Prototype “XE” and “SK” parts began to arrive in June, after which the first development engines were built for use in dynamometer tests for carburetion and tuning and to complete the calibrations required to satisfy Ford’s general production acceptance specifications (GPAS) and federal emissions requirements.

By July, there were enough parts available to permit assembly of a few test vehicles equipped with the development 428 engine, an automatic transmission, and 3.50 gears. Ford had obtained a 400 CI Firebird and a GTO for comparative performance testing, which included a series of evaluations of carburetion, exhaust systems, drive trains, suspensions, and tires that continued through the end of the month. The program was very focused on ensuring that the additional power of the 428 could be harnessed and applied to the pavement.

Ford’s standard for acceleration tests was to instrument a test vehicle and then collect data for 0-4 second and 0-10 second acceleration trials from a standing start. The instruments would record the distance travelled after 4 seconds then again after 10 seconds and could also be set up to record ¼-mile ET and MPH. The team was elated when a prototype red 1967 428 CJ Mustang coupe recorded a 0-10 second distance of 793 feet at the Dearborn Proving Grounds which was, by far, the longest 0-10s distance that they had ever recorded. Its best ¼-mile time was 13.4 seconds at 108 mph. In comparison, the 1968 390 GT Mustang recorded a 631-foot distance.

While development of the 428 CJ moved forward at Ford, Tasca continued to keep the pressure on by building their own version of a street performance car based on a lime gold 1967 390 GT Mustang coupe. Tasca replaced the 390 with their own engine assembled from readily available stock parts starting with a 428 Police Interceptor short block, C4AE-H low-riser heads, a dual quad intake, and custom headers. They named this car the “King of the Road 428” or KR-8.

According to Bill Holbrook, Jacques Passino, the Ford Division Marketing manager and Bill’s boss, bet Bob Tasca a lunch that Ford could put together a production vehicle that would outperform Tasca’s car. Holbrook had already been working on an experimental engine using all “off the shelf” components with one of his mechanics, Ernie McEwen. The basic components used were a 427 block with a 428 crank which resulted in 447 cubic inches of displacement with 427 heads and a single 780 CFM carb with a fresh air system for wide open throttle operation.

In late July 1967, Tasca drove the KR-8 to Dearborn for the demonstration/race. Holbrook recounts that even though the Tasca car jumped the start on all three runs, the 447 Mustang was able to pass and then pull away to a bus length lead at the finish line in each of three races. Once the demonstration was over, Ford kept the KR-8’s engine for comparative testing. Tasca found a 427 tunnel port engine stored in the Dearborn development garage and had it installed in the KR-8 for the trip back to Rhode Island. The KR-8 was eventually totaled when Bob Tasca Jr. lost control of it on wet pavement and ran into a telephone pole.

The Cobra Jet development program moved forward with drivability and emissions tuning in August and September 1967. These steps were required for every production vehicle and included extensive dyno testing early on followed by vehicle testing at the Dearborn test track and then later at the Kingman, Arizona test track where vehicle sign offs were normally completed.

Driveline improvements required to withstand the increased torque of the new engine combined with improved traction included the big input/output “NASCAR” toploader transmission and a larger 11½-inch diameter pressure plate for standard shift cars or a heavy-duty C-6 automatic transmission with the larger “R” code servo and a cast iron tail housing, a 9-inch nodular carrier with the “Daytona” pinion support, a new 4-pinion “traction-lok” differential, and 31-spline axles.

428 CJ Mustangs were equipped with the “Competition Handling” suspension which consisted of a 15/16-inch diameter front sway bar with special 3/8-inch thick spacer between the sway bar brackets and the mounts, mandatory power front disc brakes, higher rate front and rear springs, and staggered rear shocks to address excessive wheel hop encountered in standard shift cars. 428 CJ Mustangs and Cougars were also equipped with a ram air induction system including a fiberglass hood scoop and a vacuum operated door in a special air cleaner top that opened under full throttle to direct cooler air to the engine.

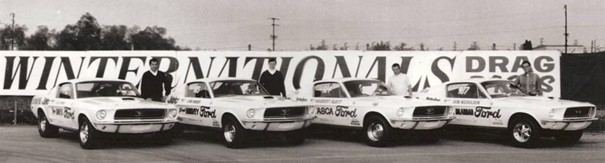

In early October 1967, Jacques Passino and Chuck Foulger travelled to the Holman-Moody-Stroppe facility in California to begin preparations for the introduction of the 428 CJ Mustangs at the 1968 NHRA Winternationals that were to be held February 2 – 4, 1968 at Pomona, California. They, along with Bill Holbrook and Al Turner, continued to work closely with H-M-S as they developed the chassis, driveline, and tire combination for these cars up until the weekend of the event.

The “428 Cobra Jet” program was revealed to the public in the fall of 1967 when Hot Rod magazine published their November 1967 issue, likely written in August 1967, which included a review of the KR-8 as well as Bob Tasca’s commentary on the lack of competitive Ford street performance vehicles. The first page of the article had a ballot box with the suggestion that votes should be sent to Henry Ford.

In a March 1968 follow up article announcing the creation of the 428 CJ, Hot Rod claimed about 2000 of the “ballots” were marked and sent to Ford. This may be true, however the 428CJ development effort had been well underway by the time the initial article was published and it is likely that Tasca used the interview to set the stage for the release of the 428 CJ.

An internal memo written in early November 1967 by Donald Frey to Lee Iacocca responding to Iacocca’s request for information about what was being done to address the issues noted in the Hot Rod article. In it, Frey details the upcoming release of the “427 Cobra Jet”, high ratio axles, and a torque sensitive locking axle followed by more performance and image models to come in 1969.

Steady progress was also being made in marketing Ford’s new performance cars. A Ford memo to dealers that detailed two stage “Highway-Drag Performance kits” for 390-428 engines, 427 engines, and 428 Cobra Jet engines was released in early November. The highway performance kits included 3.89 gears, a 427 dual point distributor, steel core wires, and a PI intake. The Drag strip performance kit included the C8AE-J heads with lightweight valves and 12.5:1 pistons. It also recommended installing a Detroit Locker differential and 31 spline axles.

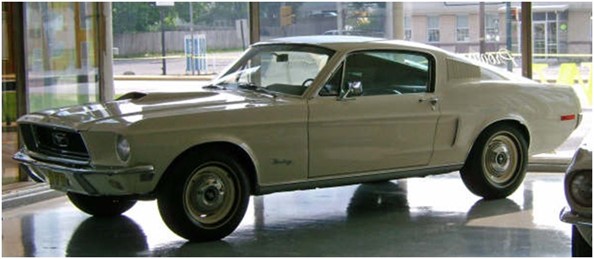

Image courtesy of the Bill Barr collection.

In early December 1967, another Ford document was written that included blueprint specifications for the 428-4V Cobra Jet followed closely by a requirements document for the 50 “135” cars. This document included the specification that 20 of the “135” cars were to be sealer and sound deadener delete and also specified that the suspension should be the same as the “Mustang 427-S” among other items. 50 cars would have to be produced and documented to satisfy NHRA Super Stock class requirements for minimum production. The Engine and Foundry Division then issued a special build communication directing that 50 engines be built for the 428 Cobra Jet program prior to December 15, 1967, for installation at the Automotive Assembly Division plant. The engines were to be based on the 428 Police Interceptor with about 1½ pages of “add and delete” selections listed including cylinder heads, pistons, bearings, valves, flywheel and clutch, etc. to be procured using a blanket purchase order.

In mid-December 1967, 4 Mustang fastbacks were built at the San Jose plant and transferred to Holman-Moody-Stroppe to be prepared for the Winternationals. It is likely that there was at least one additional Mustang built during the fall and used to develop and validate the chassis and suspension modifications that would be used on the actual race cars.

On December 26, 1967, Jacques Passino, Ford’s Special Vehicles Activity manager sent a telegram to all Ford regional and district sales managers announcing the 428 Cobra Jet Mustangs. The notice stated that effective December 26, 1967, orders would be accepted for a limited number of Mustang 2+2 hardtops (fastbacks) that would be pre-built to set specifications. The price for each car would be $2,907.67 wholesale with an MSRP of $3,612.69 including a 12 and 12 warranty. The telegram went on to state that when ordering, the buyer should indicate whether or not sealers and sound deadeners should be deleted. On the following day, December 27th, the 50 “135” series Mustangs were built at the Dearborn assembly plant.

On January 16, 1968, Chuck Foulger sent out a request for certificate of origin for the 50 cars that included the VIN’s and destination for each car. Kevin Marti of Marti Auto Works has confirmed that 135008 through 135037 were standard while 135038 through 135056 were “lightweight” cars. Foulger also sent a telegram to John Cowley with the VIN numbers of four “135” cars that would be sent to H-M-S to be modified for dragstrip use at the NHRA Winternationals.

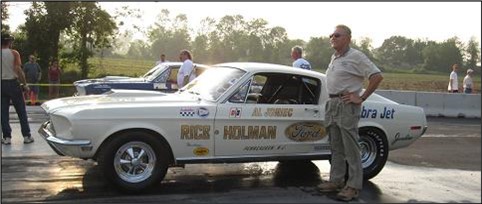

The story of the 428 CJ Mustang “invasion” at the 1968 Winternationals is well known. Ford brought six 428 CJ Mustangs to the race and the team’s performance met all expectations as four of the cars made it to their respective class finals. Al Joniec won both his class (defeating Hubert Platt in an all-CJ final) and the overall Super Stock Eliminator (defeating Dave Wren) for the Super Stock Eliminator title.

Bill Barr remembers that Foulger and Passino brought the trophy back to Dearborn with them and brought it to the office to celebrate the win with the development team. The trophy, along with a sign listing the class winning ET and mph run during the event, remained on display there for several years.

In late January 1968, an intra-company communication was sent from the Lincoln-Mercury division to the Engine and Foundry Division requesting a contact who could provide 30 428 Cobra Jet Engines for use in 10 Cougars and 20 Cyclones that were being expedited through the Dearborn (Cougar) and Lorain (Cyclone) assembly plants. The letter goes on to state that two engines were needed immediately in order to support commitments made with “buff magazines”.

Ford division must have made a similar request as we have registered two 1968-½ Mustang GTs that were bucked in February and three more that were bucked in late March. There is also an April 1968 article in Popular Hot Rodding magazine covering a green 428 CJ Torino.

Ford released the 428 CJ for production and began accepting orders for cars on April 1st, 1968. Regular production for 428 CJ Mustangs began on April 10, 1968, and quickly picked up momentum. Ford records indicate that by May 15, 1968, 352 428 CJ-powered Mustangs had been built in Dearborn, 11 had been produced in San Jose, and another 265 had been built in Metuchen for conversion to Shelby GT500KRs.

By the end of the 1968 model year, Ford and Mercury had built 1,299 428 CJ Mustangs and 1,571 GT500KRs. The success of the 428CJ continued in 1969 with a total of 14,663 428 CJ Mustangs built during the model year. By 1970, competition for sales from the Boss 302 and the Boss 429 plus a general reduction in performance car sales resulted in 3,489 428 CJ Mustangs being produced. Through all 3 years of production, 428CJ Mustang production totaled 19,451 units.

We’d like to thank several people for providing information and insight into the sequence of events that occurred during the development of the 428 CJ. Primary among these is Bill Barr, who spent many hours with us detailing Ford’s development process and identifying the members of the development team that created the 428 CJ. Bill Holbrook provided the story of the bet between Jacques Passino and Bob Tasca. We’d also like to acknowledge Dennis Kolodziej for providing information and insight related to the various blueprints for the 428 CJ cylinder heads and intake.